Products

Material (Beryllium Copper)

Product lineup

Beryllium Copper Material

We offer in plate and round bar shapes.They are mainly manufactured by forging and drawing, supplyied size is following.

Plate: max. t300mm × w600mm × L1200mm

Round bar: Max. φ200mm × L1000mm

Chill Vents

Our chill vents offer high thermal conductivity to enable the setting of ample clearances. They help improve gas exhaust efficiency and increase product yields.

In addition, since vent lengths can be made shorter than with SKD materials, they make compact designs possible.

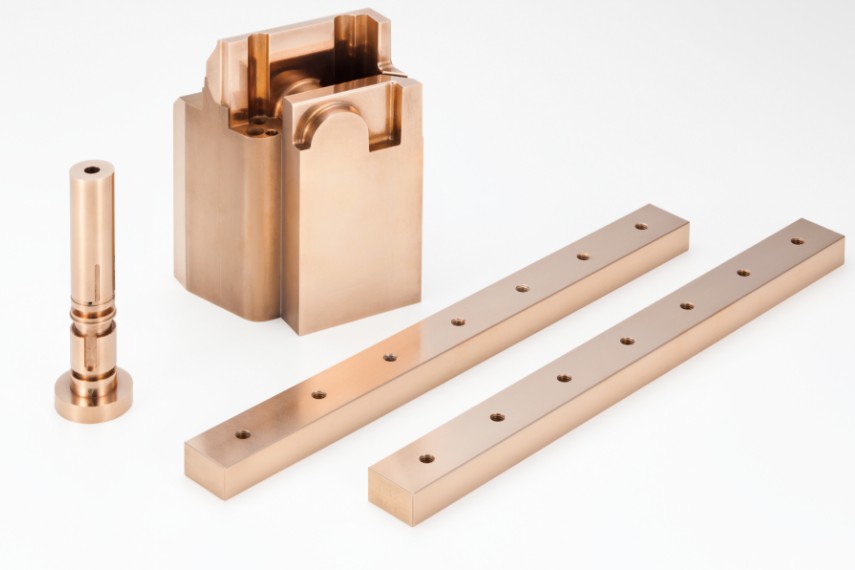

Wrought Products

Beryllium copper alloy offers various superb characteristics, including mechanical strength, wear resistance, and corrosion resistance. Parts made of this alloy are widely used in aircraft, construction machinery, and submarine repeater casings.

We offer the products in customer-specified shapes and dimensions.

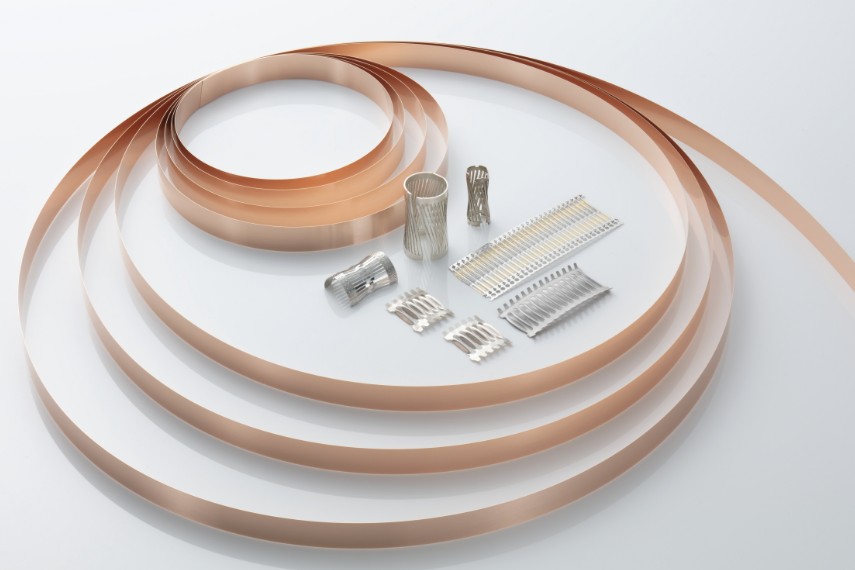

Beryllium Copper Strips

Our mainstay products, beryllium copper strips, are supplied in sheet, strip, or rod form. The material offers an optimal combination of mechanical and physical properties, including mechanical strength, thermal conductivity, fatigue strength, thermal behavior, machinability, and corrosion resistance, making it ideal for various springs.

Regulations and Safety of Beryllium Copper

Regulations

Our standard beryllium copper (an alloy containing 2% or less beryllium) is not regulated under the Japanese Industrial Safety and Health Law, the Ordinance on Prevention of Hazards due to Specified Chemical Substances, and EU chemical substance regulations such as REACH, RoHS, and ELV.

Safe

When commonly used beryllium copper is handled in its solid state or as a finished product, during pressing, machining or bending, it poses no health risk and requires no special hygiene considerations.

On the other hand, if fumes or fine dust are generated during melting/casting, spark erosion, welding, dry grinding/polishing, considerations such as ventilation and the wearing of masks are required, as with general metals.

Laws and regulations governing beryllium copper alloy and beryllium(NGK INSULATORS, LTD.)

Contact

If you have any concerns or questions regarding the handling of beryllium copper alloys, please contact us.

Upon request, we can also provide safety verification services such as work environment measurements.

Inquiry about Products

NGK FINE MOLDS, INC.

- Chubu Sales Office +81-52-884-2611