Products

Chill Vents

Overview

Beryllium copper with excellent cooling efficiency solves chill vent challenges

Beryllium copper chill vents with high strength and thermal conductivity, exhibit the following four effects and efficiencies.

- (1) Avoidance of molten metal flash

- (2) Reduction of defect rate

- (3) Prevention of aluminum seizure

- (4) Compactification

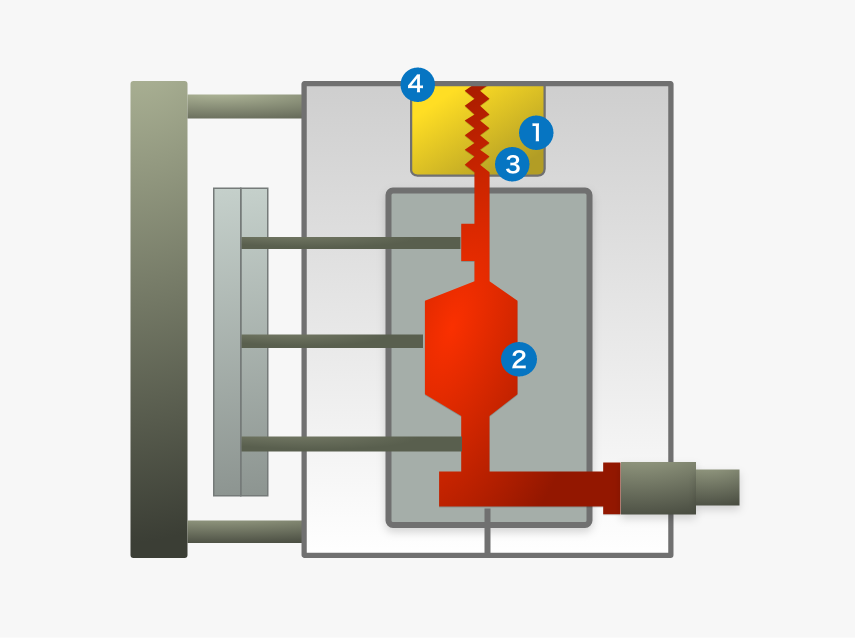

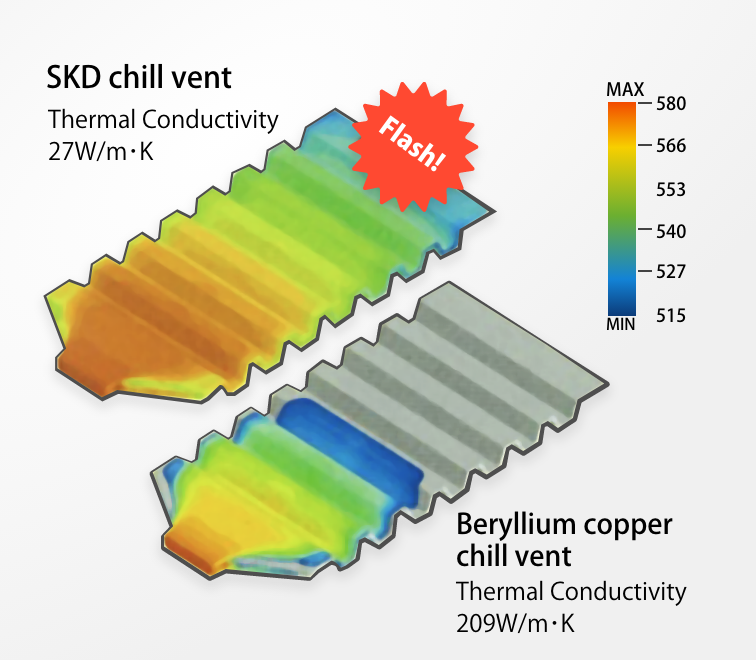

Avoidance of molten metal flash

Steel chill vents (e.g., SKD61) retard the solidification of molten aluminum, make a risk of flash.

Beryllium copper chill vents, which have up to 7 times the thermal conductivity of steel, have excellent heat heat absorption that quickly release air from the mold and instantly stop the flow of molten metal, preventing flash.

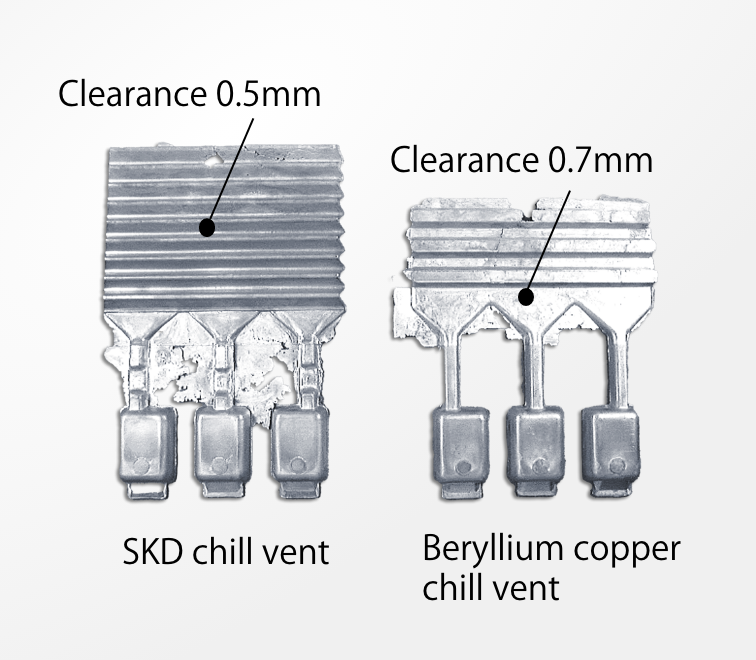

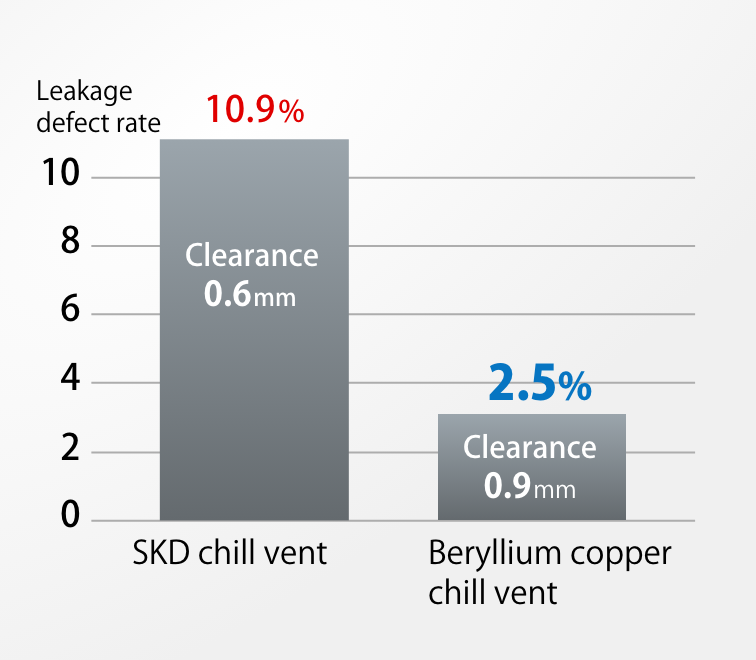

Reduction of defect rate

The high cooling effect allows the gas exhaust cross-sectional area to be set larger, and the degree of freedom in casting conditions such as speed and pressure can be expanded.

In addition, the efficiency of degassing is dramatically improved, and the leakage defect rate can be reduced.

Experimental data

Product: transmission case

Die casting machine: For 1,600 ton

Gate speed: 48m/s

Number of vents: 12

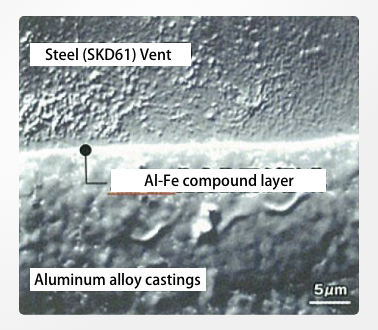

Prevention of aluminum seizure

SKD61 chill vents form Al-Fe compound layer, and cause "seizure".In addition, the compound layer is expands the thick wall, which may cause problems such as cracks and damages.

Beryllium copper chill vents do not form an Al-Cu compound layer, and prevent seizure, so it is maintenance-free such as cleaning and no production problems.

Compactification

Beryllium copper chill vents make quick cooling, allowing for a more compact design than SKD61.

In addition, the constraint of the mold area is reduced, so it is possible to halve the length of the chill vent.

Experimental data

Chill vent model: E-CL9 (C Block)

Clearance: 0.9mm

Material: ADC12 Gate speed:10m/s

Molten metal temp.: 580°C Solidification temp.: 515°C

Hybrid chill vent

If the manufacturing conditions of die casting are harsh, there is a concern about the occurrence of melting and cracking.

As a countermeasure, a "hybrid chill vent" in which a steel material (SKD61) is reinforced with beryllium copper bases, and achieve life prolongation.

Inquiry about Products

NGK FINE MOLDS, INC.

- Chubu Sales Office +81-52-884-2611