Products

Wrought Products

Overview

Processing comparable to general steel materials is possible

It is possible to process by applying appropriate processing conditions that take into account the characteristics of beryllium copper, processing the same as general steel materials.

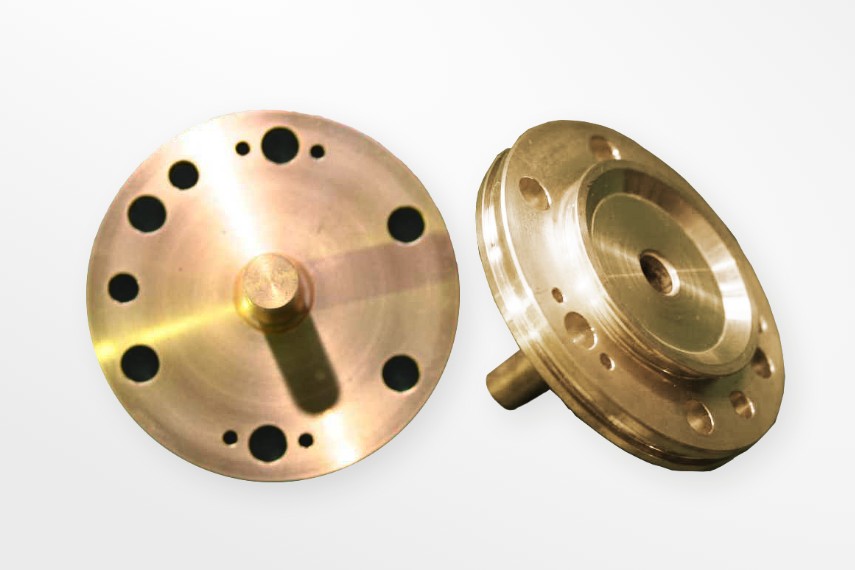

Machining (Lathe Machining , Drilling, End Milling)

Like copper alloys, the melting temperature of beryllium copper is low, so it tends to weld and burr easily, but there is no problem if the cutting edge cooling is enough.

Arc Electric Discharge Machining (EDM, Wire Cut, Welding)

Beryllium copper has high electrical conductivity, resulting in higher current and voltage settings. Therefore, electrodes, wires and welding rods wear out faster than steel materials, so care must be taken.

Lathe Machining

Since beryllium copper has higher cutting resistance at lower cutting speeds, it is necessary to cut at higher speeds than general steel materials, while taking care to avoid temperature rise.

| Category \ Cutting conditions | Cutting speed (m/min) |

Feed speed (mm/rev) |

Depth of cut (mm) |

Cooling method | Cutting tool | |

|---|---|---|---|---|---|---|

| Roughing & semi-finishing processing | Beryllium copper BeA-25 ULTRA |

18 - 350 | 0.3max | 0.75 - 1.25 | Water-soluble or oil-based coolant | Carbide Tips (Coating) |

| Prehardened steel Equivalent to HRC 40 |

40 - 60 | 0.7 | 6 - 8 | |||

| Finishing processing | Beryllium copper BeA-25 ULTRA |

180 - 350 | 0.05 - 0.15 | 0.1 - 0.2 | ||

| Prehardened steel Equivalent to HRC 40 |

40 - 60 | 0.7 | 6 - 8 | |||

Drilling

Beryllium copper is drilling under almost the same conditions as general steel material.

| Category \ Cutting conditions | Cutting speed (m/min) |

Feed speed (mm/rev) |

Cooling method | Cutting tool | others | |

|---|---|---|---|---|---|---|

| Roughing, semi-finishing and finishing processing | Beryllium copper: BeA-25 ULTRA Prehardened steel: Equivalent to HRC 40 |

Almost the same conditions as general steel material (Step drilling) | Center through (WET) | Carbide Drill | Recommend chip evacuation and cooling to reduce heat during drilling. | |

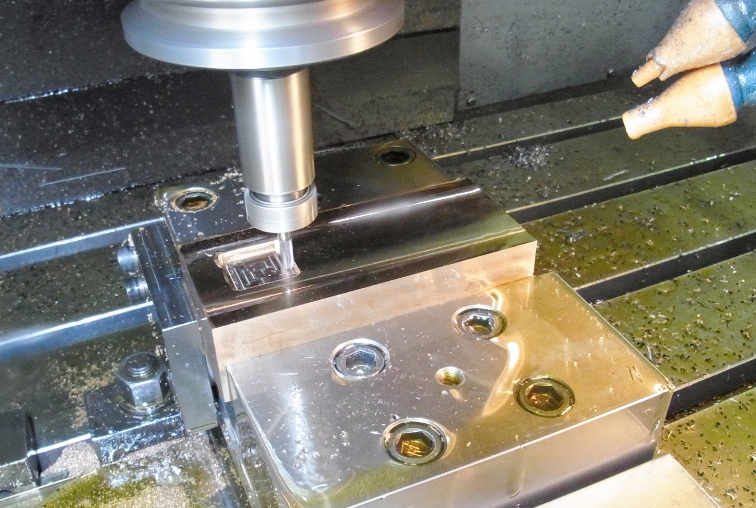

End Milling

Beryllium copper is end milling under almost the same conditions as general steel material.

| Category \ Cutting conditions | Cutting speed (m/min) |

Feed speed (mm/rev) |

Cooling method | Cutting tool | |

|---|---|---|---|---|---|

| Roughing, semi-finishing | Beryllium copper: BeA-25 ULTRA Prehardened steel: Equivalent to HRC 40 |

Almost the same conditions as general steel material | Center through (DRY or AIR) | Carbide Tipped End Mills | |

| Finishing processing | Center through (WET) | Solid Carbide End Milll | |||

Wire Cut Processing

Beryllium copper is wire cut processing 1.5 to 2.0 times faster than general steel materials.

Remarks

- The condition is a case of using brass φ0.300mm, and it is necessary to adjust the conditions depending on the material, size, and processing machine.

- High-speed machining tends to make the machined surface rough, so 2nd and 3rd cuts are recommended when high accuracy and surface roughness are required.

| Wire material/size | Cutting speed (mm/sec) |

Tension (N) |

Pre-tension (N) |

Average processing voltage (V) |

Offset amount | Machining speed (mm/min) |

|---|---|---|---|---|---|---|

| Brass φ0.300mm | 200 | 13 | 14 | 55 - 65 | 1/100 | 0.75 - 1.90 |

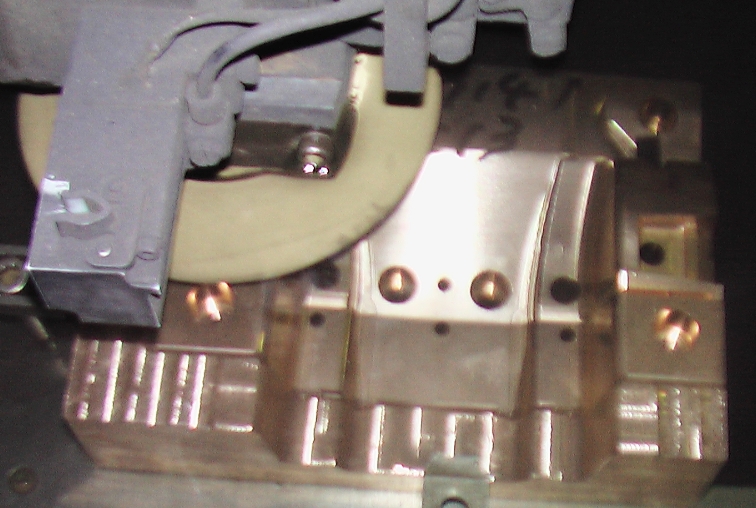

Electric Discharge Machining

Beryllium copper has poorer EDM workability than general steel materials, but has good surface roughness.

Remarks

- Electrode wear is about twice that of steel electrodes, and discharge time tends to be longer. (In contrast, newer EDMs seem to have improved on this, so please contact the respective manufacturers for details)

- Surface roughness is better than that of steel, and polishability is excellent due to the absence of a machining transformation layer.

| Category \ Cutting conditions | Electrode material | Peak current value (A) |

Duty factor (%) |

Machining speed (mm³/min) |

|---|---|---|---|---|

| Roughing processing | Brass, Copper alloy Graphite |

Under steel +10 - 15 |

65 - 80 | 30.9 |

| Finishing processing | 1.3 |

Welding

Beryllium copper is welding under specific conditions.

Safety Precautions

- As with general metal welding, work in an environment with an exhaust system such as a duct.

TIG welding

| Preheating temperature (°C) |

Welding current (A) |

Polarity | Welding rod | Argon gas flow rate (L/min) |

|---|---|---|---|---|

| 200 - 280 *Please note that temperatures above 350°C will soften the material. |

150 - 200 *Beryllium copper has good electrical conductivity, so it requires three times the current of steel. |

Alternating Current | Material: BeA-25/BeA-11 (Exclusive co-material) Rod diameter: φ0.8-φ3.0 (Selected according to base metal and welding range) |

20-23 |

Laser welding

| Welding power (W) |

Irradiation speed (Hz) |

Current value | Welding rod | Argon gas flow rate (L/min) |

|---|---|---|---|---|

| 150 - 200 |

0.5 - 15 | 150mJ-90J CPC | Material: BeA-25/BeA-11 (Exclusive co-material) Rod diameter: φ0.3-φ0.6 (Selected according to base metal and welding range) |

4-6 |

Inquiry about Products

NGK FINE MOLDS, INC.

- Chubu Sales Office +81-52-884-2611