Products

Molds for Tires

Overview

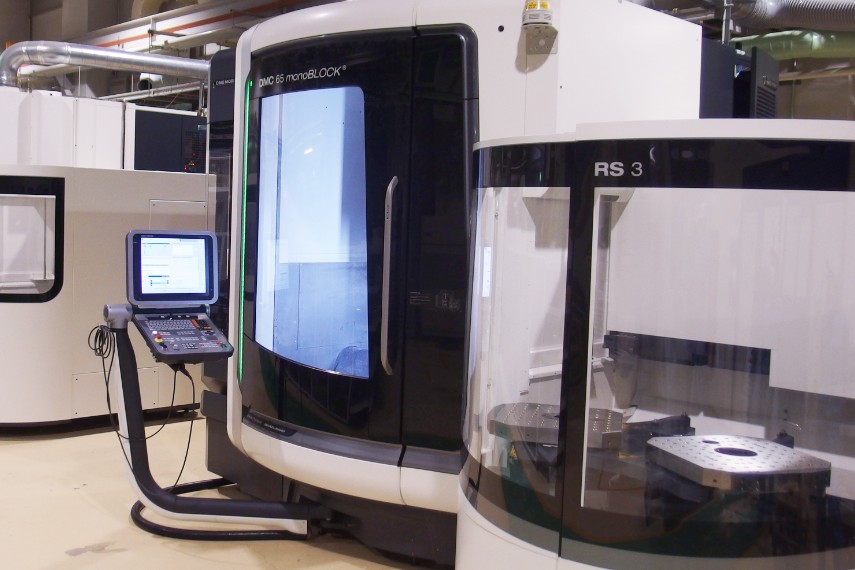

We use CAD/CAM and 5-axis processing machines to make master models of complex shapes.

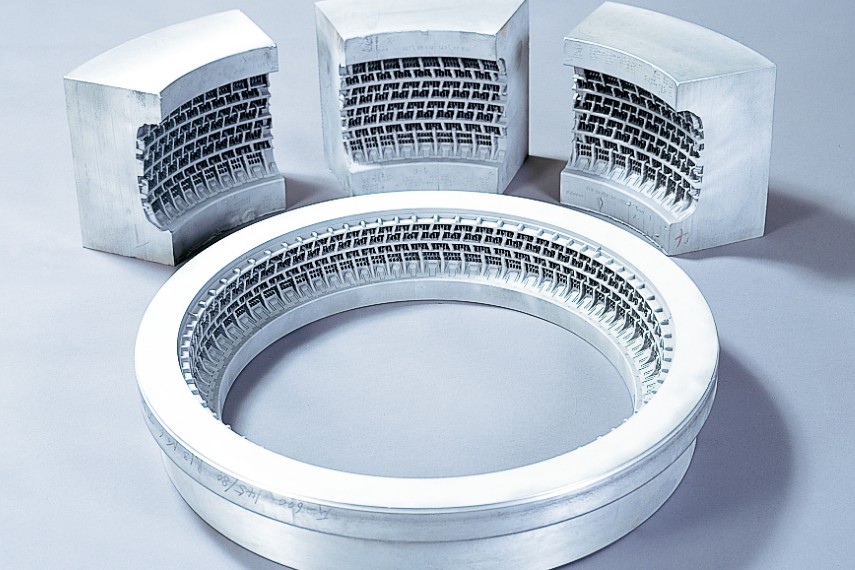

Next the master modelds are transferred to aluminum alloy using precision casting technology, and then process the periphery using a turning center (large vertical lathe) to produce tread rings and sectors for tire molds.

We also specialize in manufacturing large tire molds for construction vehicles.

Processing examples

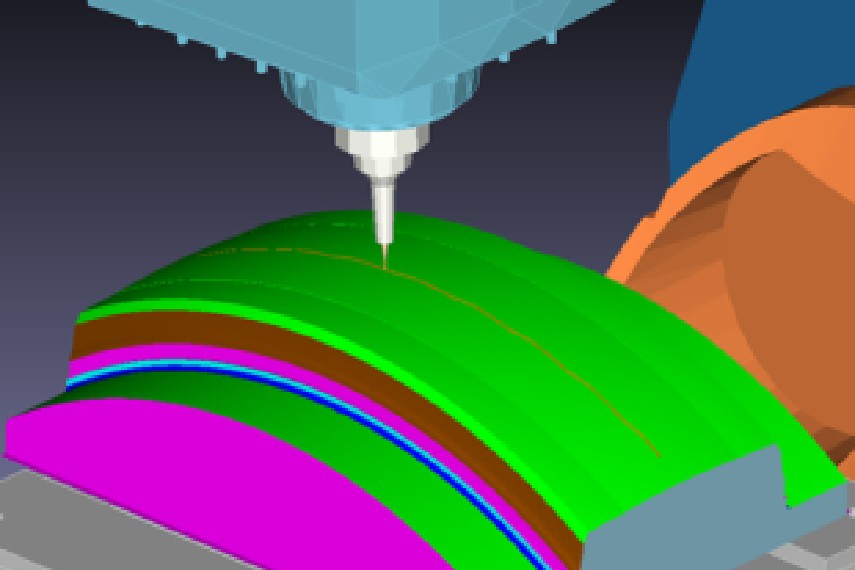

5-axis machining technology

5-axis machining technology that enables complex master models in a short time

Manufacturing a mold for a tire requires master models that allows accurate reproduction of complex tire shapes.

Based on customer-supplied data, we can quickly make master models of complex shapes using our customized CAM (Computer Aided Manufacturing) software and simultaneous 5-axis machining center (numerically controlled automatic machine tool).

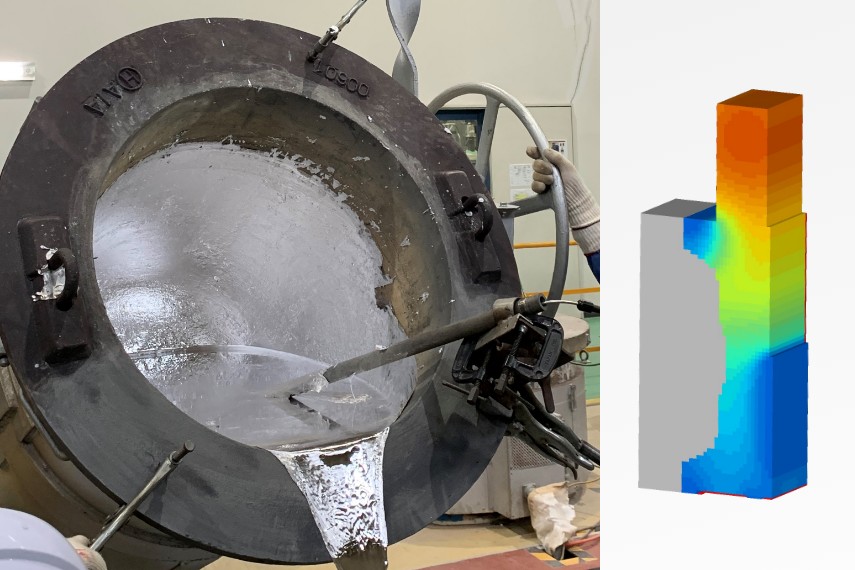

Precision casting technology

Fabrication of aluminum alloy castings transferred from the master model

We achieve high quality and defects free for both small and large molds by using a unique casting method that use casting simulation.

Turning center

Machining capability: max φ1600mm×H800mm

We operate two turning centers for tire mold machining and meet customers' delivery requirements even during the busiest times.

Inquiry about Products

NGK FINE MOLDS, INC.

- Chubu Sales Office +81-52-884-2611